Automation: My View on Cost-Cutting in Medical Bed Production

How does the smart factory reduce the cost of producing medical examination beds? I’ve seen how automation is changing the way medical exam beds are made. It offers clear and real ways to save money. In my opinion, smart factory automation cuts costs in several important ways:

Efficiency Boosts: Automated production lines work faster and are more steady than people working by hand. For example, As a medical examination bed manufacturer,Grace Medy’s smart automated factory really shows these benefits. They do this by making every step in the making process better. I believe the speed and consistency here are major advantages.

Steady Quality: Automated systems make the quality of each exam bed better. I find that robotic arms and wireless devices ensure every bed meets tough healthcare rules. This means fewer mistakes and less need to fix things, which is a big plus.

Lower Labor and Energy Bills: With new automation systems, medical examination bed manufacturers can check how processes are running in real time. Based on my experience, these systems find the best ways to make things. They adjust to save energy, make work easier for staff, and cut the costs of running the factory.

Better Safety: Automation means fewer people do dangerous jobs. This makes the workplace safer. It also cuts down on risks that can stop work or increase insurance costs. I think this safety aspect is very important.

How Automation Affects Medical Examination Bed Making

From what I’ve seen, for making exam beds, automation leads to:

A big drop in waste,

Faster production of many beds,

Lower overall costs to make them,

Better quality that’s the same every time.

Technology like robots and sensors helps manufacturers make products very accurately. People working by hand just can’t match this. This is really important because medical devices must meet strict safety and usability standards. I feel this precision is a must-have.

Using Digital Tools and New Technologies in medical examination bed production

Going digital and using automation go together very well. I see medical examination bed manufacturers are now using AI for analysis, robots for putting beds together, sensors that give instant data, and even 3D printing. These new ideas help to:

Get products to market faster,

Use equipment more,

Make sure safety rules are met,

Help the whole factory produce more.

So, I believe smart automation is not just a passing trend. It’s a key plan for medical device makers who want to cut costs and stay ahead of the competition.

Data Analytics and Smart Manufacturing for Medical Beds

I see smart medical bed factory changing how companies make medical examination beds. In my opinion, data analytics is at the core of this shift. When manufacturers use data analytics, they can find hidden patterns and connections in their operations. This helps them make smarter choices and improve how things work. I’ve noticed this lowers production costs and improves product quality.

Predicting Failures to Keep Production Running |

I think a big advantage of manufacturing intelligence is failure prediction. Smart systems track live data from factory equipment. They can then warn managers about potential equipment issues before they occur. This means less downtime for machines. It also means fewer interruptions that add to expenses, and a quicker fix for problems. In my experience, all these factors save money and keep output steady. |

Watching in Real-Time and Making Automatic Changes |

I suggest using IoT sensors. These allow managers to monitor every machine and process live. If equipment starts to act up, the system alerts staff at once. There’s no need to wait for someone to spot a problem. People can fix issues fast. This keeps the factory operating well. For large-scale production, automated calibration ensures machines stay precise. They don’t need constant manual tweaks. This ensures each medical exam bed meets strict industry standards. |

Connecting ERP, MES, and QMS Systems |

I recommend smart factories use software such as: * ERP (Enterprise Resource Planning) * MES (Manufacturing Execution Systems) * QMS (Quality Management Systems) These platforms gather and automate data collection and reporting from one central point. This makes it easier to find production issues or quality risks fast and then deal with them. Based on my experience, as more factories use these systems, the good results increase. We see fewer mistakes, better documents, and more reliable medical bed quality. |

Using Analytics for Custom Manufacturing |

I find another key benefit is personalized manufacturing. With advanced analytics, companies can adjust bed designs. They can also change production methods. This allows them to meet the unique needs of different hospitals and patients. For example, I’ve seen the latest analytic tools help create custom-shaped headboards. They also aid in producing bed boards with exact welds. This adaptability is achievable when large volumes of factory data are well-organized and thoughtfully analyzed. |

For medical examination bed manufacturers, I believe these data-driven systems prompt positive changes. They can inspire improvements even before problems surface. They help keep each manufacturing stage on target. They also ensure every bed meets strong safety and quality rules. From what I’ve seen, this all adds up to real savings. Smart factories can cut their production costs by as much as 30% with these approaches.

Ways Grace Medy Use to Cut Manufacturing Overhead

I think smart factories are changing how medical examination beds are made. They use automation, data analysis, and lean methods to cut overhead costs. Let me show you how Grace Medy use these methods can lower production costs by up to 30%.

Automating Repetitive Work

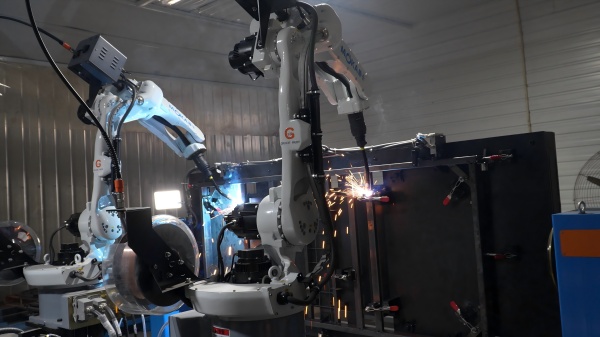

Robots and Machine Vision: I’ve seen Grace Medy medical bed factory robots and vision systems take over tasks like putting parts together, welding, and moving them. This means less need for people to do this work. Production lines can also run all the time, 24/7.

What happens: Labor costs go down. Production becomes more consistent. Human mistakes happen less often.

For instance: In my experience, factories using robotic lines see clear cuts in labor costs and get more products made.

Using Lean Manufacturing Ideas

Getting Rid of Waste and Improving Workflow: I believe lean methods focus on cutting out steps that aren’t needed. They also help reduce making too much product and make moving materials smoother. Mapping the workflow is a good way, in my view, to find and eliminate extra steps.

The Results: Lean manufacturing typically cuts costs by 5% to 20% in the first year. Fewer products have defects, with defect rates dropping by 25% to 90%.

Always Getting Better: I suggest regular check-ins and process improvements. This way, the savings keep coming and aren’t just a one-time thing.

Combining ERP and Process Management Tools

One Digital System: From what I’ve seen, Grace Medy ERP software connects money matters, the supply chain, making products, and reports all in one place online.

The Upsides: Automatic resource handling reduces office costs. It also gives a live, clear view of what’s happening.

What happens then: Managers can find problems with efficiency or quality fast. Then, they can take specific steps to fix them.

Saving Energy with Smart Controls

New Energy Systems: I recommend upgrading to machines that use less energy and using smart controls. This really cuts down on utility bills.

Checking Energy Use: Doing energy checks helps factories discover more ways to save on their utility costs. I think this is a smart move.

Improving Facility Layout

Better Layouts: Grace Medy redesign their production floors. This cuts down on needless movement and holdups. This makes everything work more efficiently.

In my opinion, when smart factories use all these ways to cut overhead, they save a lot of money regularly. I believe this method is why we now see a 30% cost cut in making medical examination beds.

Summary

I’ve seen these changes up close. For me, smart factory automation is not just about saving money. I’m sure it’s about completely changing how we make medical equipment. The 30% savings are impressive, that’s clear. But what I find truly exciting is something else. I know that every examination bed we make well means better healthcare for patients. More manufacturers are using these technologies now. So, I believe we’re moving towards a future. In my opinion, this future will mean high-quality medical devices are easier for everyone to get and easier for them to afford.