Which Parts Of A Medical Bed Can Be Customized?

Think medical beds are just metal frames with mattresses? Most people focus on basic features like height adjustment or side rails. But here’s what healthcare pros know: headboards and footboards can transform patient care in ways you’d never expect.

Wood finishes calm anxious children. Built-in electrical systems make critical procedures run smoother. These parts do much more than frame the bed.

The right customization boosts staff efficiency. It also speeds up patient recovery rates.

Headboards and Footboards

Headboards and footboards are key parts of a medical bed. You can customize them to meet different care needs, design preferences, and patient requirements.

Material Options

Medical bed headboards and footboards come in sturdy composite materials and wood laminates. Dynarex provides both composite and laminated wood options. These include finishes like Walnut, Mahogany, Wild Cherry, and Light Oak. You can also find ABS plastic, aluminum, and stainless steel options. I recommend these for hospitals that need durability and easy cleaning.

Size and Installations

Standard widths are 36″ or 42″. Bariatric and specialty beds offer expandable options up to 48″. Many products allow for tool-free or quick-adapter installations. This makes them easy to fit or replace. Some models come pre-bored for seamless integration into existing beds.

Style and Design Variations

Facilities can choose from multiple design styles. These include Standard, Classic, Shaker, or child-friendly models with specialty motifs. I’ve seen artistic and pediatric styles used in children’s wards. They create a comforting environment.

Color and Finish Customization

A wide palette of standard and custom colors is available. This lets care facilities match the headboard and footboard to the overall room décor. Custom vinyl covers are also available from independent sellers. They tailor products for home settings.

Enhanced Functionality

Advanced headboards and footboards feature integrated systems. These include lighting, electrical outlets, rails, and mounting tracks for IV poles or infusion pumps. In modern hospital settings, you’ll find sliding rails for accessories. There are outlets for medical gases and even voice recognition for patient alerts.

Real World Examples and Suppliers

Dynarex: Expandable and adapter-ready headboards for bariatric beds.

Hekman Contract: Solid wood, pre-bored sets for institutional use.

Etsy: Custom linen-style covers in a wide range of colors for residential care.

Grace Medy: Bulk and custom headboards in ABS, aluminum, or stainless steel for both hospitals and home users, with order quantities from 1 to 100 pieces.

I believe customizing headboards and footboards gives hospitals and care facilities flexibility. It enhances both aesthetic appeal and functional convenience. Based on my experience, this supports patient wellbeing and staff efficiency.

Side Rails Customization Options for Medical Beds

Side rails are a critical safety and comfort feature. They can be customized for various healthcare environments and patient needs.

Material Selections

You can choose metal (aluminum, stainless steel) for maximum durability. Wood offers a softer touch and visual warmth. Blow-molded polypropylene (PP) provides a lightweight, easy-clean solution.

I recommend padded and plastic-coated options for pediatric wards or dementia care units. They reduce injury risk and match specific décor.

Dimensions, Configurations, and Adjustability

Rails come in full-length, half-length, quarter-length, and split designs. You can adjust them between 13″ and 42″ in length. This fits both bariatric and standard hospital beds.

Head rails measure 1000 × 600 mm. Foot rails measure 820 × 571 mm. JIECANG offers these sizes.

Staff can adjust height and angle for transfer safety and patient access. Some bed models offer motorized rail movements for added ease.

Control Features and Technology Integration

Integrated controls support up to 12 buttons on the rails. The footboard can have up to 19 buttons. Features include synchronized drives, emergency release, and IPX6 water-resistance.

Electric side rails make operation easier for patients and caregivers. They work well in high-acuity clinical settings.

Based on my experience, customization of side rails ensures optimal safety, comfort, and usability. Different care settings need different options. This impacts both patient outcomes and clinical workflow.

Bed Frame and Extension Kits Customization

The bed frame is the structural core of a medical bed. It is one of the most customizable parts. You can adjust it to fit different care settings and patient needs.

Key Customization Options

Flexible Sizing: Standard specs are just the baseline. You can expand the frame width up to 54 inches, which is huge for bariatric comfort. Need extra length? Simple extension kits take the bed from 80 inches to over 88 inches. Meeting different patient needs is actually pretty straightforward.

Height & Weight Capacity: You get a lot of range here. The beds lowers to just 19 inches, making it much safer for patients to get in and out. As for strength, the reinforced steel frame steadily supports anywhere from 300 to over 600 lbs. You’re getting durability without compromising on safety.

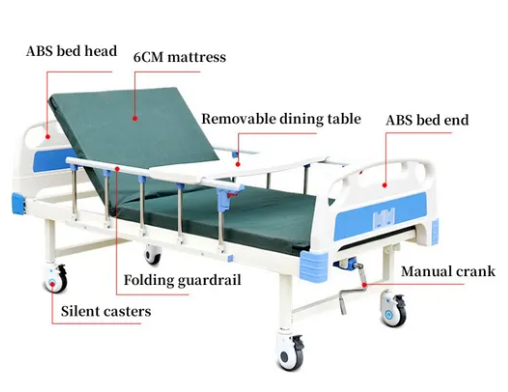

Materials & Functionality: The core is built from heavy-duty steel. But you can soften the look with wood or composite finishes to fit a home environment perfectly. We also threw in quiet casters, a central locking system, and broad side rail compatibility. It’s all designed to make daily care workflows smoother.

In my experience, customizable bed frames and extension kits deliver flexible solutions. They are adjustable in width, length, and height. They have reinforced construction and advanced mobility features. These changes support both clinical efficiency and patient comfort. They adapt well to the different needs of hospitals, rehab facilities, and home care.

Mattress and Support Surface Customization Options for Medical Beds

Medical Mattresses and support surfaces matter a lot for patient comfort. They also help manage pressure and improve healthcare results. I’ve seen many customization choices available. These suit different patients, facilities, and care needs.

Material, Layering, and Support

Foam Selections: I recommend choosing from high-density foam for durable support. Memory foam, latex, and gel-infused options provide better pressure relief. Plant-based foam is a good eco-friendly choice.

Innerspring Constructions: Custom innerspring units add traditional support. The 13-gauge 5-turn Bonnell springs are popular.

Layer Customization: Mattresses can have single or multiple layers. Each layer serves specific needs. A channel-cut foam layer helps redistribute pressure. You can create distinct zones (up to five) for varied pressure management across the mattress.

Thickness: Options range from 4″ to 12″. Common profiles like 6″, 6.5″, and 8″ are standard. Any custom height can be produced to meet your requirements.

Cover Fabrics and Performance Features

Healthcare-Grade Covers: Choose nylon, Dartex™, or medical vinyl. Each resists fluids. They have antibacterial and antifungal properties. They resist stains and are antistatic and non-allergenic.

Inspection and Replacement: 360° zippered covers make inspection easy. You can remove or replace covering materials quickly.

Special features include fire barrier fabrics. Fluid protection flaps surround zippers. Breathable or stretchable organic cotton covers improve patient safety and infection control.

Compliance: Many products meet 16 CFR Part 1633 and other federal fire protection standards.

Institutional and Bulk Order Options

Healthcare brands offer custom logo embroidery. This supports institutional branding.

Discounts are available for bulk orders. Institutional purchasing programs provide savings.

Casters and Braking System Customization for Medical Beds

I recommend customizing the casters and braking system of a medical bed. It makes a big difference in mobility and safety. Pay attention to wheel material, size, load, mounting, and braking style. This ensures the right match for hospital, rehab, or home care settings.

Medical Bed Caster Materials and Wheel Types

Polyurethane, Monotech, Vipor, neoprene, and soft gray rubber offer strong durability. They provide quiet operation, non-marking surfaces, and grip across various flooring.

I suggest gray soft rubber wheels for hospital beds. They minimize noise. They protect sensitive floors in patient areas.

MRI rooms may order electromagnetic-safe casters. Labs handling electronics require ESD (Electrostatic Dissipative) wheels.

Eco-friendly and maintenance-free caster materials are available. Facilities prioritizing sustainability and hygiene prefer these.

Wheel Size, Weight Capacity, and Mounting Options

Common wheel diameters range from 4″ (250 lbs max) to 5″ (300 lbs max). Heavy-duty options exist for bariatric beds or extra equipment.

You can select single or twin wheel setups. This helps balance stability, maneuverability, and weight demands.

Braking System Customization: Individual, Central, and Smart Solutions

Individual Locks: Classic medical beds use four casters. Two lock and two don’t lock. Each has a lever for manual operation.

Central Operated Brakes: Modern hospital beds often feature a total-locking system. All wheels lock or release from one foot pedal or central bar. This boosts speed and safety for staff and patients.

Based on my experience, choosing the right caster and brake customizations has a big impact. It affects medical bed performance, staff safety, and patient comfort. I recommend you request the right materials, dimensions, lock types, and hygiene features. This ensures the best fit for each care environment. Hospitals benefit from silent, non-marking wheels. Specialized labs need unique ESD options. Smart, central locking systems raise safety and efficiency to a higher level.

Control System Customization

The control system is the command center of any medical bed. Hospitals and care facilities can now tailor these systems for smooth patient care and better workflow.

Types of Bed Control Systems

Medical beds offer several control interfaces to meet different care needs:

Manual Crank Systems: Best for basic settings or tight budgets. No power needed.

Wired Pendant Controls: The industry standard. It offers simple push-button operation for all major bed adjustments. Both caregivers and patients find it easy to use.

Motors and Actuators Customization in Medical Beds

Motors and actuators form the core of modern medical bed flexibility and automation. I believe their customization directly affects bed performance, patient comfort, and how efficiently staff can work.

Key Customization Options

Stroke Length and Range: You can customize the stroke length to match different bed designs or adjustment needs. Beds can be set up for high, low, or extended movement ranges. This is important for ICU or bariatric use.

Load Capacity: Actuators handle different patient weights. Models range from 200 lbs for standard beds to 600+ lbs for bariatric use. This keeps beds stable no matter the patient profile.

Speed and Response: You can adjust actuator speed settings. Choose smooth, gentle motion or rapid adjustment for emergencies. Fast-response actuators work well in critical care. Quick bed repositioning is vital there.

Actuator Coordination and Bed Movement

Multi-Actuator Synchronization: Beds usually have multiple actuators. Each controls a different zone—head, midsection, and foot. Synchronized operation keeps all sections moving together. This prevents jamming or uneven movement.

Bed Segment Functionality: Custom actuator setups support advanced bed functions. These include Trendelenburg, reverse Trendelenburg, lateral tilt, and zero-gravity positioning.

IV Pole Customization Options for Medical Beds

I recommend customizing IV poles to fit different patient care needs. You can pick from various materials, features, setups, and add-ons. These choices help you meet specific healthcare needs.

Material and Finish Choices

IV poles come in chrome-plated steel, 304 stainless steel, or white powder-coated finishes.

These materials last long. They help control infections. They also match different décor or branding styles.

Some models offer color padding choices (up to 8 colors). You can choose Cream, Gray, Blue, or Purple. These colors improve visual appeal.

Height and Adjustability

Most poles have manual telescoping adjustment. You can use a threaded thumb-locking collar, hand crank, or foot lever. These tools make height changes easy.

Standard heights adjust from 30 inches (for pediatric use) to over 60 inches for adult beds.

Height-locking systems provide safe support during therapy. I find them reliable.

Stable Base and Mounting Design

Choose from weighted bases or spider-legged designs. Models with 5 or 6 legs offer great stability.

Base sizes include 16″, 22″, and 24″. These sizes prevent tipping. This is true even with multiple IV bags or pumps attached.

You can mount IV poles anywhere on the headboard or footboard. Flexible brackets make this possible.

Hooks, Accessories, and Equipment Integration

Pick from 2, 4, or more ram hooks. They can be removable or fixed. Your choice depends on patient and facility needs.

Poles can hold receptacles for IV pumps, hex bar, or round bar setups. These secure fluids and devices during critical care.

Evaluation

Based on my experience, customizing IV poles improves workflow. It also enhances patient therapy. Hospitals, ambulatory care, and long-term care centers gain from matching pole design to clinical tasks. You might need to handle multiple IV bags. Or you might need to add medical devices. Or you might need to guarantee stability in emergencies. I suggest choosing the right setup for your needs. This flexibility keeps therapy organized and safe. It supports staff efficiency. It improves patient outcomes.

Custom Accessories for Medical Beds

Customization Impact

You can choose the right accessories for your needs. This addresses fall prevention, pressure sore management, and patient mobility. It also helps with organizational needs. Hundreds of options are available. Based on my experience, every clinical or personal care scenario can find the right fit. This helps maximize safety, comfort, and workflow.