What Affects Adjustable Medical Bed Freight Costs

Multiple factors determine freight costs for adjustable medical beds. Each variable connects to others and impacts your final expenses.

-

Bed Dimensions & Weight Impact

-

Shipping Method Options & Cost Implications

-

Geographic & Location Variables

-

Specialized Equipment Requirements

Shipping Method Options and Cost Implications

Pick the right shipping method. This choice saves you hundreds of dollars or locks you into competitive rates. Medical bed freight breaks down into three main categories. Each has its own cost structure and best use.

Truckload vs. Partial Truckload vs. LTL

Truckload (TL) shipping gives you an entire truck for your order. You get the lowest per-unit costs on large quantities. Your beds don’t share space with other cargo. Transit times stay predictable. No extra handling at distribution centers. This cuts damage risk. TL works best for facilities ordering 10+ beds or filling 80% of a trailer’s capacity.

Partial Truckload (PTL) fits orders of 2-5 beds. You pay for the trailer space you use. Not the whole truck. Costs fall between TL and LTL rates. PTL carriers pair your shipment with similar freight going the same way. This method suits mid-sized orders. LTL premiums hurt your budget. But you can’t fill a full truck.

Less Than Truckload (LTL) handles 1-2 bed shipments. Your freight shares truck space with cargo from other customers. Carriers charge higher rates. They handle complex routing and frequent loading/unloading. LTL fits small orders, sample purchases, or emergency replacements. Per-unit costs run higher. But you get more shipping flexibility.

Equipment and Handling Cost Add-Ons

Standard freight quotes don’t include special equipment needs. Forklifts or pallet jacks are required for safe loading and unloading. These aren’t optional extras. They’re requirements in your final invoice. Request quotes that show equipment costs listed out. Or check if they bundle into the base rate.

Ramps give trailer access at facilities without loading docks. Many medical facilities and nursing homes lack dock-height platforms. Without ramps, your delivery stops before beds reach your door. Check ramp availability before booking shipments.

Straps and padded blankets protect beds during transport. Quality securing materials stop shifting, scratching, and component damage. Proper padding costs far less than insurance claims for damaged goods. Industry data shows HME providers face 37% cost increases from manufacturer and distributor labor expenses. Shipping protection costs rank as secondary drivers.

International Shipping Options

Cross-border medical bed shipments add extra cost layers. Sea freight offers the most budget-friendly option for bulk international orders. Container shipping slashes per-unit costs. But transit times stretch to 3-6 weeks. This method fits planned facility expansions or large-scale equipment updates.

Air freight costs 3-5 times more than ocean shipping. Save this option for urgent replacements. Or high-value specialty beds. Or situations where long lead times create problems. Air transport makes sense once bed shortages cost more than premium shipping rates.

Land transport serves regional cross-border movements well. Truck shipments between nearby countries balance cost and speed better than air freight. Plus, you avoid ocean shipping delays. Know the customs clearance requirements and border crossing rules. This prevents surprise holdups.

Compare Multiple Carriers

Carrier rates for adjustable medical bed freight vary by 30-50% on the same routes. Shop around. This is your fastest way to cut shipping costs.

Request Quotes from 3-5 Carriers Minimum

Get detailed quotes from at least three carriers. Five is better. Carriers use different pricing models. Some charge per-mile rates. They take distance and apply a fixed cost per mile. Others use zone-based pricing. This groups regions into rate tiers.

Calculate the total cost for your specific distance with both methods. A per-mile carrier might quote $2.50 per mile for 800 miles ($2,000 total). A zone-based carrier charges a flat $1,650 for the same route. The zone-based option saves you $350. But this flips on shorter routes where per-mile rates win.

Look Beyond Base Freight Rates

Base rates tell part of the story. Weight handling capacity matters for bariatric beds over 500 pounds. Some carriers add overweight surcharges of $150-$300. Others include heavy freight in standard pricing. Ask upfront about weight limits and extra fees.

Check what equipment comes included. Does the quote cover forklifts and ramps? Or do these add $75-$150 per delivery? Bundled equipment access cuts your final invoice.

Route Consolidation Opportunities

Shipping multiple beds to nearby facilities? Ask carriers about route consolidation discounts. Combine deliveries headed to the same region. This drops per-unit costs by 20-35%. Carriers prefer grouped shipments. They’ll share savings to win bulk business. One provider saved $1,200 each month by coordinating regional deliveries through a single carrier.

Optimize Packaging and Break Down Beds Before Shipping

Break down adjustable medical beds before you ship them. This cuts your freight costs big time. A full bed takes up premium trailer space. The same bed in parts fits standard LTL rates and smaller containers.

How Size Affects Freight Costs

Standard hospital beds measure 36-40 inches wide and 80-88 inches long. These sizes push you into expensive shipping categories. Full-size beds need dedicated truck space. Or they need special flatbed trailers. Both options cost much more than standard freight.

Breaking down beds changes this. Take the bed apart into pieces. Now you’re working with boxes sized 36×24×12 inches. These fit standard LTL shipping pallets. Carriers charge by size and weight for smaller packages. Your costs drop 60-70% versus shipping whole beds.

Grace Medy shows smart packaging. Their three-function hospital beds ship with two bed frames in one box. Accessories for both beds go in a second box. This cuts packaging volume. Fewer boxes mean lower freight bills.

Better Weight Spread

Adjustable medical beds weigh 150-500 pounds based on features. Bariatric models weigh even more. Ship them whole and you get weight focus problems. Carriers must use heavy-duty gear. Uneven weight can overload the trailer. This breaks regulations and pushes you into costlier shipping.

Breaking down parts fixes this. Four packages of 50-90 pounds each spread weight across trailer space. Standard pallet jacks handle the load. You don’t need special forklifts. You don’t need flatbed trailers. You get full load use without weight fees.

Select Appropriate Incoterms for Control

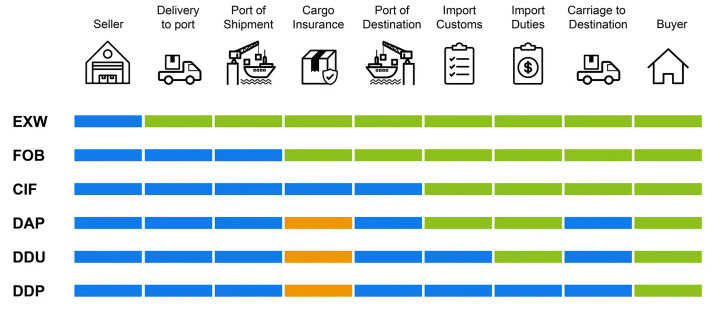

Incoterms determine who pays freight costs, when risk transfers, and who handles customs paperwork. The wrong choice hands control to someone else. The right choice keeps freight expenses in your budget.

Common Incoterms for Medical Bed Shipments

EXW (Ex Works) puts maximum control in your hands. The seller makes beds available at their facility. You arrange everything else: pickup, freight, insurance, customs, delivery. This works well with established carrier relationships and negotiated volume rates. You save 15-25% versus seller-arranged shipping. The catch? You need logistics expertise and time to coordinate international movements.

FOB (Free On Board) splits responsibility at the port of origin. Sellers handle export clearance and loading onto the vessel. You pay ocean freight, insurance, import duties, and final delivery. FOB gives you control over the ocean voyage—the most expensive shipping leg. Lock in your own freight forwarder rates. Skip the supplier markups of 20-35%.

CIF (Cost, Insurance and Freight) shifts more work to sellers. They pay ocean freight and basic insurance to your destination port. You handle import clearance and inland delivery. Sounds convenient, right? But sellers often use higher-cost freight partners. They mark up shipping 25-40%. You lose negotiating power. CIF makes sense for small orders where your shipping volume doesn’t unlock better rates.

DDP (Delivered Duty Paid) means sellers deliver beds to your door with all costs paid. Zero logistics work for you. But you pay premium prices. Sellers add 30-50% margins on freight, duties, and handling. DDP works for urgent single-bed replacements—not for bulk orders where freight costs matter.

Match Incoterms to Your Shipping Volume

Order 1-2 beds per year? CIF or DDP saves time without major cost penalties. Your small volume won’t get better rates.

Order 5-10 beds per year? FOB delivers the best balance. You control ocean freight—the biggest cost component. Sellers handle export paperwork that’s tricky for you.

Order 20+ beds per year? EXW maximizes savings. Your volume unlocks 20-30% freight discounts. Hire a customs broker for $150-$300 per shipment. You still save thousands versus seller-arranged shipping.

Track Hidden Costs in Different Terms

EXW requires you to pick up beds at the supplier’s location. Add $200-$500 for local pickup and export handling if you lack ground staff there.

FOB and CIF seem to include everything to port. But destination port charges hit your invoice as a separate line item. Terminal handling fees run $75-$150 per shipment.

DDP quotes look clean. Ask for itemized breakdowns. Compare the freight portion against your own carrier quotes. Suppliers often pad DDP shipping by 40-60%.