Comparing Stainless Steel and Carbon Fiber for Medical Bed Manufacturing

Which material leads medical bed manufacturing between stainless steel and carbon fiber?

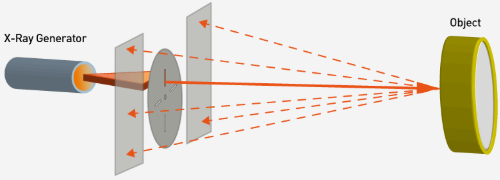

X-ray Transmission Efficiency

Carbon fiber medical beds, in my experience, let up to 97% of X-rays pass through. I find this allows for clearer medical images. It also means staff do not need to reposition the bed or patient as often during procedures.

Stainless steel, on the other hand, tends to obstruct X-rays. I’ve observed this requires medical staff to move the bed often to get accurate images. This can lead to longer procedure times and, I believe, higher radiation exposure for the patient.

Weight and Maneuverability in medical bed manufacturing

Carbon fiber beds are about 45% lighter than standard stainless steel beds. I think this is a considerable difference.

Looking at density statistics: Carbon fiber is 1.5-2.0 g/cm³. Stainless steel is much heavier at 7.8-8.0 g/cm³.

This reduced weight makes carbon fiber beds easier for staff to move and position. I suggest this is a great advantage in emergency rooms and operating rooms.

Mechanical and Structural Performance in medical bed manufacturing

Carbon fiber offers high stiffness. This ensures the medical bed, in my opinion, keeps its shape under heavy patient loads. However, if the design isn’t precise in the medical bed manufacturing, it can be more brittle than metals.

Stainless steel medical bed combines good stiffness with flexibility. I find it resists bending well and shows resilience during active medical use.

Practical and Clinical Benefits

I recommend carbon fiber operating tables because they allow for full-table X-ray imaging without needing to move the patient. This feature, from my perspective, lessens staff workload. It also helps minimize the patient’s radiation exposure.

Carbon fiber does not react much with chemicals and strongly resists corrosion. It can handle long exposure to alcohol, medications, and blood. I find it is also easier to keep clean in hospital settings.

Price and Cost Considerations

Carbon fiber generally has higher initial costs. This is because its manufacturing method is more involved. For situations where light weight and high strength are vital, I believe this expense is often acceptable.

Stainless steel beds are usually more cost-effective for large-scale making. I think they are suitable when the bed’s weight is not a primary issue.

Medical Equipment Applications

I’ve seen carbon fiber being chosen for advanced medical uses. These include surgical robot arms, radiotherapy tables, breast exam trays, medical headrests, and special fixation plates for cancer treatment.

Stainless steel, in my observation, is still common in more standard, budget-focused hospital bed designs.

Direct Comparison Table: Stainless Steel vs. Carbon Fiber Medical Beds in medical bed manufacturing

| Feature | Stainless Steel | Carbon Fiber |

|---|---|---|

| Durability | I find it has high durability. It resists corrosion. It’s good for everyday hospital use. | I believe this material is very durable. It has a great strength-to-weight ratio. |

| Weight | It weighs 7.8-8.0 g/cm³. I observe it’s much heavier. This makes the beds harder to move. | It weighs 1.5-2.0 g/cm³. That’s about 45% lighter. I find repositioning is easy. |

| Initial Cost | I see the cost is lower here. It’s a good choice if you need many beds for a hospital. | The initial cost is higher. I think it suits specialized medical uses. |

| Frame Construction | The frame uses cold-rolled steel. It also has electro- and powder-coating to make it strong. | This frame is an engineered composite. I note it’s light yet stiff. |

| X-ray Transparency | It blocks X-rays. This means you might need to move the patient or the bed. | Up to 97% of X-rays pass through. I recommend this for full-table imaging. |

| Maintenance | I find it’s easy to clean. It resists chemicals and sanitizers well. | This one is also easy to clean. It can resist alcohol, blood, and medications. |

| Lifespan | You can expect it to last 8-12 years. | It may last longer. I observe less wear on its structure over time. |

| Appearance | It has a traditional medical look. | It presents a modern, premium image. |

| Environmental Impact | Its carbon footprint is higher. Manufacturing it uses a lot of energy. | Its carbon footprint is lower. This is because of its advanced materials. |

| Bed Adjustment Features | You can adjust it manually or electrically. It offers a standard range for height and angle adjustments. | Adjustments are similar. I find they are smoother because the bed is light. |

| Compatibility with Equipment | Compatibility is good. However, I must point out it’s conductive. | I rate its compatibility as excellent. It’s non-conductive, so it’s safe with electronic interfaces. |

| Vibration Dampening | It offers minimal vibration dampening. | I believe it provides superior vibration dampening. |

| Clinical Usage | Hospitals use it often in standard wards. I feel it’s good for general purposes. | Clinics choose this for radiology. It’s also selected for use with surgical robot arms and in oncology. |

Key Point: I think your final choice depends on your main needs. If you require a lighter bed that’s easy to move for radiology or complex surgeries, I’d suggest carbon fiber is a good investment. If you need a cost-effective, strong bed for regular hospital use, I recommend stainless steel as it’s a reliable option.

Conclusion: Stainless Steel vs Carbon Fiber Medical Beds – Which Is Best for Modern Healthcare?

From my perspective, when you’re choosing between stainless steel and carbon fiber for making medical beds, your decision depends on your facility’s main needs for daily operations and patient care.

Key Advantages of Carbon Fiber Medical Beds in medical bed manufacturing

Significant Weight Reduction: Carbon fiber beds are about 45% lighter than stainless steel ones. This makes it much easier for staff to move the beds. I find this is very helpful in surgery and emergency situations.

Superior X-ray Transmission: Carbon fiber allows X-rays to pass through very well, at rates of 97% or higher. This means you don’t have to move patients as often. I’ve seen this speed up medical tasks. It also reduces work for the staff and lowers radiation for patients.

Exceptional Strength-to-Weight Ratio: Carbon fiber is very strong for its weight. It has a tensile strength between 2.5-7.0 GPa (up to 6,000 MPa). This is much stronger than stainless steel, which is 0.5-1.5 GPa. So, you get strong support, but the bed stays light.

High Chemical and Corrosion Resistance: I appreciate that carbon fiber holds up well against common hospital cleaners, medicines, and blood. This helps the beds last longer and stay clean.

Operational Efficiency: Carbon fiber beds have special features that work well with imaging equipment. I believe this improves how things run in radiology, cancer care, and surgery.

Ideal Applications for Each Material

I’d recommend carbon fiber if:

– You need beds that are light and easy to move often.

– Your facility focuses on high-tech imaging tests.

– You need beds that will last a long time and resist chemicals. I think this is key for many settings.

– You can afford to spend more at the start because the long-term work benefits are worth it.

Based on my experience, stainless steel is a good option if:

– Keeping costs low is your main goal.

– The beds will be in places where they might take a lot of hits or are used for general needs.

– You need the frame to conduct some heat or be recyclable.

Final Thoughts

Carbon fiber medical beds or operating tables do cost more to begin with. But, in my opinion, they offer real benefits like better imaging, easier movement, and longer life. I suggest that for hospitals doing complex surgeries, radiology, or wanting top work efficiency, carbon fiber is the way to go. It really is the leading edge for medical bed tech. Stainless steel is still a practical, money-saving choice for everyday hospital use and for when you need to buy many beds.

In the end, I believe the right material for you will come down to what your facility needs most. You’ll have to balance the work advantages with what you can afford.