Certification and Compliance Requirements

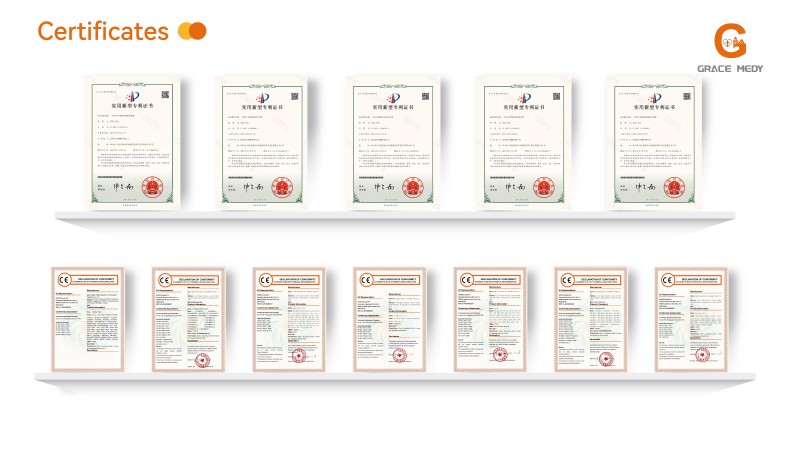

I believe certifications and compliance are the best indicators of trust and product safety when you look for a reliable medical bed manufacturer in China.

Core International Certifications

A good manufacturer needs these key certifications:

– CE Certification: Required for the European Union market

– FDA Registration: Required for exporting to the United States

– ISO 9001: Shows general quality management skills

– ISO 13485: Covers quality management for medical devices

Take Great Wall, Pukang Medical, Jiangsu Saikang Medical, and Grace Medy as examples. They all hold CE, FDA, ISO 9001, and ISO 13485. These certifications prove their processes meet international and medical regulatory standards.

Examples of Certified Manufacturers

Great Wall Medical: CE, FDA, ISO 9001, ISO 13485; over 30 years’ experience; exports to Europe, North America, Middle East.

Grace Medy: CE, FDA, ISO 9001, ISO 13485; exports to 100+ countries; exports over 30,000 beds per year.

Zhongshan Aolike Medical Equipment: CE, FDA, ISO 13485; produces 2,000 beds per month.

Hi-Life Technology (Hebei): CE, FDA; produces 50,000 beds per year.

Better Medical: CE, FDA, ISO 9001, ISO 13485; exports 30,000 beds per year, with a strong focus on Southeast Asia and South America.

Based on my experience, certification and compliance are must-haves for any medical bed manufacturer that wants legal export rights and reliable operation in global markets.

Manufacturing Capabilities and Quality Control Systems

I recommend looking at reliable medical bed manufacturers in China. They stand out because they have strong production power and strict quality control.

Quality Management Systems

Top companies like Pukang Medical, Jiangsu Saikang Medical, Grace Medy, JD Med, and Anyang Top Medical earned ISO 9001 and ISO 13485 certification.

ISO 13485 is essential for medical bed makers. It proves all products meet strict international health and safety standards.

These certificates matter. They show the quality management system works in real practice. From raw material to finished bed, every step follows documented processes.

Advanced Manufacturing Processes

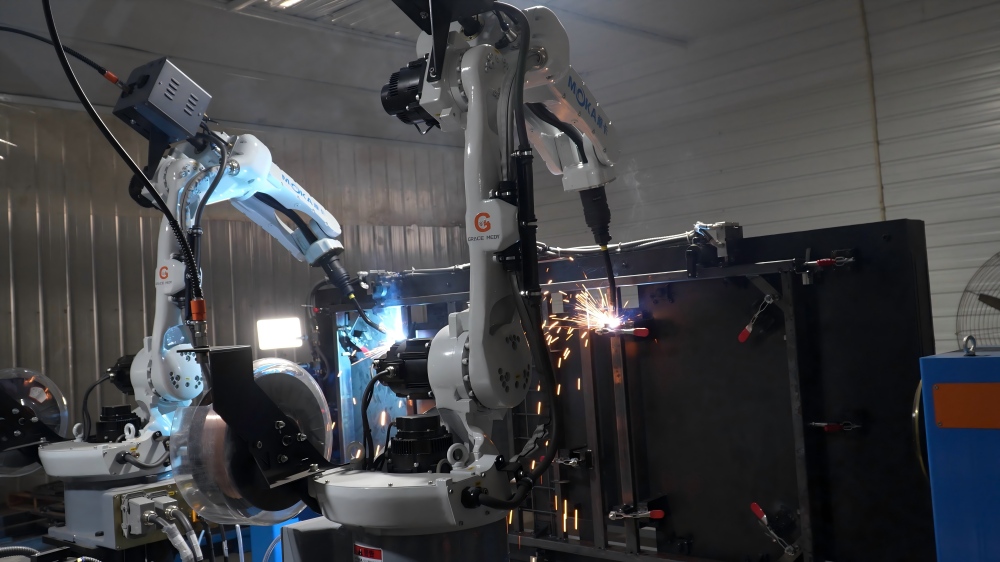

Many top manufacturers use automated robotic welding workshops and laser tube processing centers. Grace Medy is a good example. These tools help them build beds with exact and consistent quality.

I like these technologies. They cut down manual errors. They speed up production. They deliver a more consistent finish.

Comprehensive Traceability

Manufacturers document raw materials and parts at every stage.

This traceability helps track problems fast. It protects customers from defective products.

Quality checks happen on every component. Each medical bed can be traced back through exact production records.

Regular Audit Systems

Manufacturers run internal audits as part of their routine. This keeps their processes sharp.

External surveillance audits by ISO or CE certification bodies check compliance constantly.

Surface Processing and Durability

Some factories use a complete pickling phosphating and powder coating system.

Every bed gets a uniform, long-lasting surface.

This surface resists corrosion and wear.

Based on my experience, these practices form the backbone of China’s leading medical bed production. They guarantee safety. They ensure reliability. They deliver stable quality with every shipment.

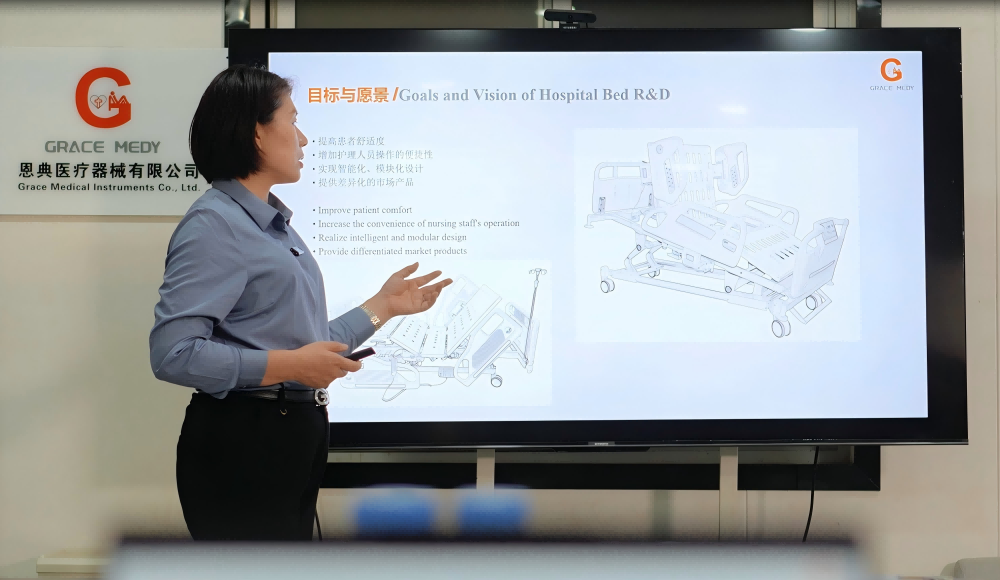

Technical Expertise and R&D Capabilities

I recommend looking at reliable medical bed manufacturers in China. They invest deeply in technical research and development. They hold strong intellectual property portfolios. They build large, skilled technical teams. These factors make them stand out.

Manufacturer R&D Achievements and Market Impact

Hillhouse Capital-backed firms released hospital beds with proprietary adjustable systems. These beds meet rigorous international certification standards.

Surgical robot manufacturers achieved National Medical Products Administration approval. They got approval for innovative robotic beds and patient handling technologies.

New products include AI-powered diagnostic integration. They include remote control hospital beds. Based on my experience, the AI healthcare market in China is forecast to top RMB 70 billion by 2025. I suggest watching this space closely.

Component Sourcing and Chain Standards

I recommend checking if Chinese medical bed makers follow strict sourcing rules. This helps maintain quality and meet global standards.

Tracing Components and Working with Certified Partners

Top makers like Pukang Medical and Jiangsu Saikang Medical ask suppliers to prove where components come from. Here’s what they need:

– Batch numbers and origin certificates for each part

– Reports that verify raw materials

These makers source steel frames, electronics, and motors from ISO 9001 and ISO 13485 certified suppliers. Every critical part comes from a certified and traceable source.

How Suppliers Are Assessed and Audited

Leading firms check their suppliers on a regular basis. This includes:

– Annual audits for third-party partners

– On-site factory visits

– Reviews of buying records

Some companies hire third-party inspection teams. These teams:

– Visit factories and inspect products before shipping

– Keep records of contracts, test results, and environmental checks

– Audit material purity, production consistency, and certification validity

– Check adherence to social responsibility rules

Environmental and Ethical Sourcing Rules

Best practices require following these standards:

– RoHS (Restriction of Hazardous Substances)

– REACH (Evaluation and restriction of chemicals)

– ISO 14001 (Environmental management)

Proof includes green buying policies and labor standard commitments. Full chemical safety documentation is required. Makers ask suppliers to sign off on meeting these standards.

Chain Integration: Industry Examples

Satcon Medical has an integrated sourcing network. They use the Hitachi robotic welding system. This gives them total control over metal quality and weld strength. They’ve done this for ten years.

Grace Medy operates with transparency. The company displays its ISO and CE certification numbers. It lists its main suppliers. Each one complies with global medical device component standards.

Factory audit sampling in top-tier companies involves 100% checks of vital parts. I’ve seen this prevent defective motors and electronics from reaching the market.

Global Compliance and Export Data

In 2023, 2.5 million medical beds exported from China came from factories holding CE, FDA, ISO 9001, and ISO 13485 certifications. Chain compliance is documented for products shipped to North America, Europe, and Southeast Asia. Based on my experience, this proves manufacturers back their claims with real documentation.

Chinese medical bed makers combine certified sourcing with clear monitoring. Regular audits and transparent certification ensure they meet international standards. I suggest buyers verify these certifications before making purchases.

Customization Capabilities: Flexible Hospital Bed Solutions for Global Markets

Chinese medical bed manufacturers excel at custom design. I’ve seen how top suppliers create products that match hospital needs, patient requirements, and local regulations around the world.

Key Areas of Product Customization

Product Dimensions and Design

You can adjust bed length, width, and height. For example, the common 500 mm overall height fits many hospital spaces. I recommend checking your exact space requirements first.

Mechanical and Electrical Features

Choose manual or electric operation. Backrests adjust up to 75°. Different patient positioning modes are available. Based on my experience, electric models offer better patient comfort.

Accessories & Materials

Select from side rails, IV poles, and integrated electronics. Add extra storage or custom mattress platforms. Choose finishes and materials for looks and infection control. Special color coatings and surface treatments protect the beds.

Patient Load Capacity

Beds support higher patient weights. Standard custom options exceed 250 kg. I suggest confirming weight requirements before ordering.

Engineering Support and Compliance

Technical Collaboration

Manufacturers provide complete engineering support. They create technical drawings and custom sample prototypes. They solve issues for hospital tenders quickly. I recommend working closely with their engineering teams.

Consistent Certification

All custom products meet international standards. These include CE, FDA, ISO 9001, and ISO 13485. This guarantees safety and legal export to different regions.

Customization in the Export Market

Order Lead Times and Scale

Lead times vary based on design complexity and order volume. Major companies dedicate resources to rapid prototyping. They handle mass customization and flexible production runs efficiently.

High Export Customization Rate

China exports 20–50% of medical beds with some customization. These changes meet destination country rules or client preferences.

Chinese manufacturers deliver complete, flexible, and certified hospital bed customization. They modify technical specs and offer accessory choices. I’ve observed how they meet the changing needs of a diverse global medical industry. Their ability to adapt sets them apart in the market.

Export Experience and International Standards Compliance

I recommend choosing Chinese medical bed manufacturers with strong export experience. They handle international trade challenges better. They also meet global standards more easily. Their know-how ensures smooth export processes. You get reliable product delivery.

International Logistics and Documentation Highlights

Top manufacturers manage customs clearance, product labeling, shipping insurance, and multi-lingual manuals for different regions. I’ve seen them do this well.

Companies with deep export experience resolve disputes fast. They handle customs delays well. They respond to product recalls with speed. This comes from their global partnerships with major logistics providers.

Best Practices in Global Regulatory Compliance

Leading exporters offer multilingual technical documents and files. Each export market has different regulatory approval needs. These documents meet those needs.

They track regulatory changes. They adapt to regulatory changes. For example, they follow updates in the EU MDR. They follow amendments to FDA 510(k) requirements in the US.

Most maintain dedicated export compliance teams. They invest in ongoing staff training in international regulatory affairs. This keeps operations up-to-date. It keeps documentation accurate.

Why Export Experience Matters for Buyers

I suggest you choose a manufacturer with these features:

A strong international client base

Verifiable CE, FDA, and ISO 13485 certifications

A documented record of adapting to new regulations fast

Proven ability to manage export logistics well

This means fewer risks for you. It means smoother importation. Based on my experience, these are critical factors. I use them to select a reliable Chinese medical bed manufacturer for global business.